Paper

Since our beginnings in the 1960’s

We have been developing original writing paper

To cultivate the unique sounds of writing by hand.

Writing is an everyday art.

MD PAPER is crafted using a blend of advanced machinery and production balanced by the eyes, skills and passion of our craftsmen, maintaining a reassuring quality to those who truly appreciate the beauty of the handwritten word.

This website introduces some of the varied production processes each product goes through in the pursuit of the perfect writing feel.

A variety of pulps are used to construct the perfect paper texture.

Pulp sheets used to create our paper are stored in an area of our factory that is about three times the size of Tokyo Dome. Pulp is made of wood, but the type of wood used changes both the texture and hardness of the finished paper.

MD PAPER is made of hardwood pulp, which can be finished with a softer texture than the strong, rigid paper made from conifers.

First the pulp is broken down in water.

Careful assessment of coloring, refining and water conditions.

Water is highly important in paper manufacturing. We carefully filter river water for the utmost purity. Because natural water changes in viscosity depending on the season, we also make sure to adjust our refining process to accommodate each season’s changes in water quality and ensure a perfect finish.

Once the pulp is broken down, it is slightly yellowish in color.

The coloring process happens while the pulp is being broken down. The unique, light-beige color of MD PAPER is born of refined craftsmanship that ensures there are not even the tiniest variations, leaving the pulp in a fibrous, oatmeal-like state once the process is complete.

Next, the pulp is turned to paper. When traditional Washi paper is made, a sieve-like tool called a sugeta (a reed for paper making) is used to scoop materials out of the water, and is then lightly shaken to filter out the material.

We use a similar process when making our paper, evenly spreading the base pulp over wires rotating at high speed.

The entire process is then completed by the eyes, hands and experience of our talented craftsmen.

Now that some of the moisture has been removed, the paper is heated and dried before being sent through hard pressure rollers to be flattened out, rolled and cut into sheets, completing the paper-making process.

This completed paper is then rigorously inspected by our chief craftsman to ensure both the appearance and texture are of the same outstanding quality you have grown to love.

Even minor compromises in any one of the processes can have a drastic effect on the end product. That’s why our professional manufacturing team remain alert and focused until the manufacturing process is complete.

Only paper that meets our highest standards is sent to you.

When the MD PAPER is complete, we perform a final test in the factory. This is an incredibly tense time, as even the most minute flaw will see the entire lot returned to pulp to be remanufactured to the correct standards.

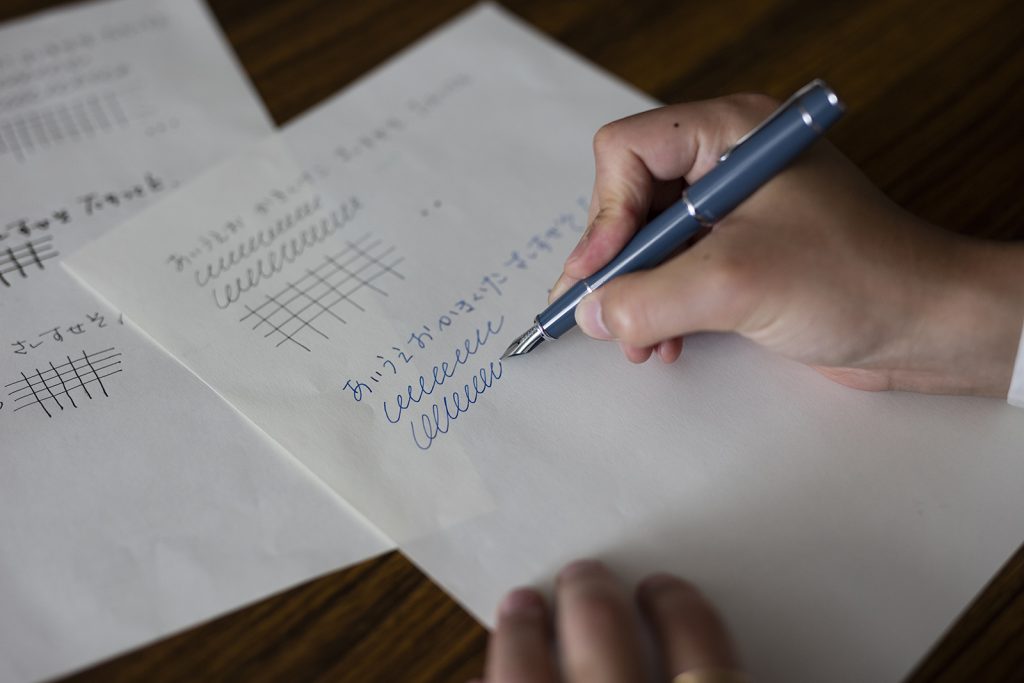

The paper is checked for a variety of specifications, such as thickness, weight and color, yet the most time-consuming of these tests is the writing quality check. This incredibly thorough test is conducted by writing characters and lines over and over using a variety of writing instruments.

We check how well the ink is taken by the paper, how it dries, and whether it bleeds through while also checking the coarseness and feel, and how they affect the writing flow. It is only when each of these tests are successfully concluded that MD PAPER is shipped as a product ready for you to enjoy.

The history of MD PAPER

The MD Notebook comes in two types of paper: MD PAPER Cream and MD PAPER Cotton.

For most of MD PAPER’s history since it was first developed in the 1960s, MD PAPER was only available in white. This paper was used in MIDORI’s Diaries, Daily Journal and Diamond Memo, and remains a long-standing favorite.

MD PAPER Cream was launched in 2006. With a warmer color that is gentle on the eye, this paper is ideal for writing with a fountain pen. It also has the perfect balance between smoothness and a little resistance, ensuring comfort and making writing a pleasure.

MD PAPER Cotton was developed in 2013, with cotton pulp used for 20% of the materials, giving it a soft, fuzzy texture. Cotton paper is also extremely durable and preservable, and has long enjoyed a reputation as high-quality paper in Europe, where it was used for important paperwork and official documents for centuries. Its fibers are longer and narrower than those of pulp, giving it a smooth, pleasing texture with a softness that feels like it is infused with air.

This cotton-soft white paper is ideal not only for classic fountain pens but for colored pencils too. This special version of MD Notebook is available only with blank pages, as a specialist art notebook.